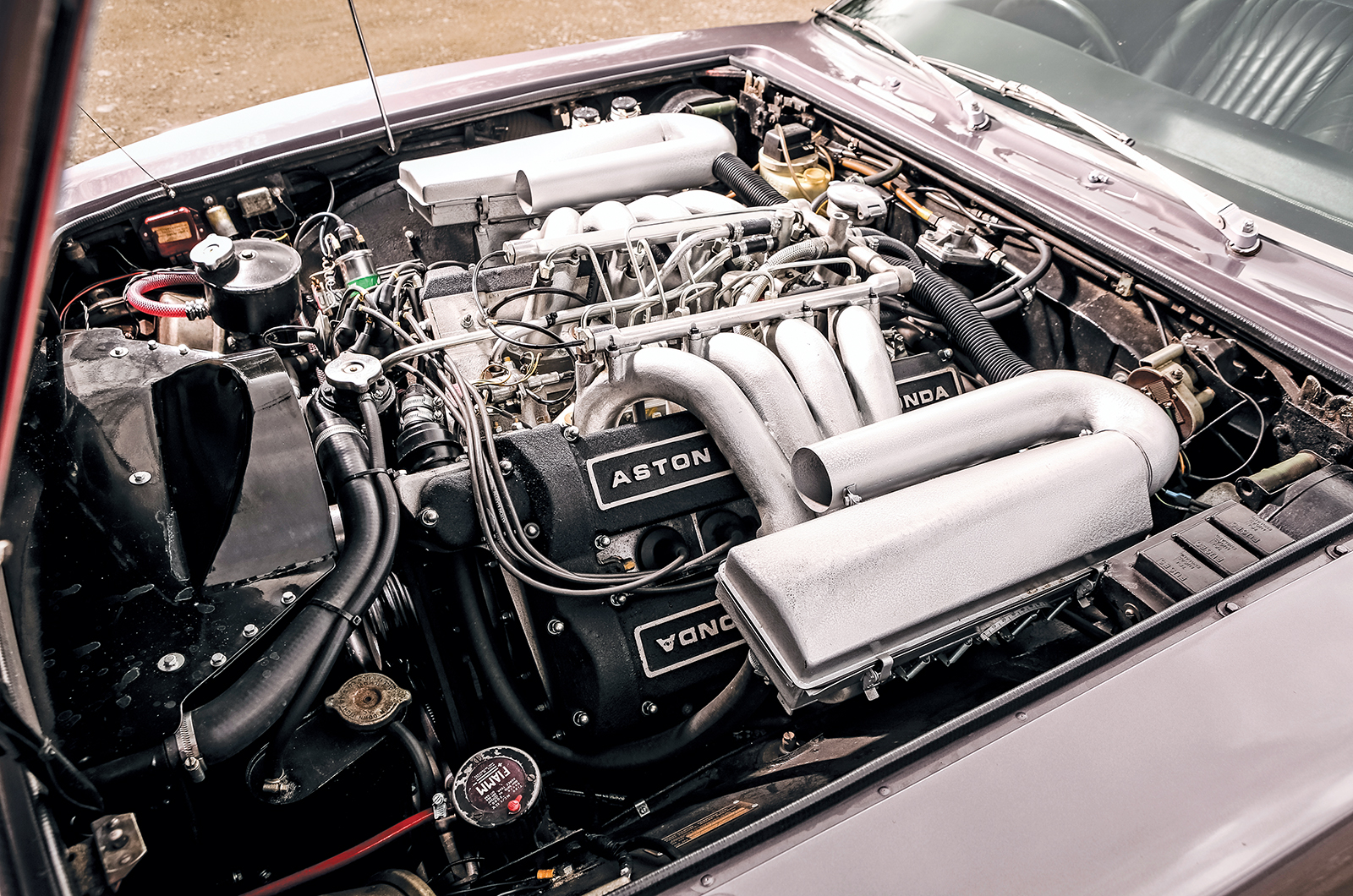

Somewhat lost in the massive engine bay, the straight-six, with that unfamiliar Brico plenum chamber, has a warm hum to it once under way and a lusty character with one foot still in the 1950s; a trait that would have made it the choice of Aston’s more traditional customers.

Which is not to say the DBS injection is slow. It churns its torque converter off the line, but has a brisk feel with refined mid-range pull. I felt it was slightly quieter and smoother than a DBS on carbs and Duckworth was pleased that the hot starting on his car was better, firing at once, while the V8 spent five seconds turning over.

Duckworth has only just rekindled his affair with his DBS, but Prevett has run his V8 for 18 years and 40,000 miles, and watched the market wake to its charms. He finds insuring it for £220k a bit of a worry.

The upside, I suggest, is that people like him are more willing to restore these once-unloved models, which is good for the cars, but only if people actually use them.

Images: Tony Baker

Specialist advice

Former Aston man Andy Chapman knows the foibles of these systems

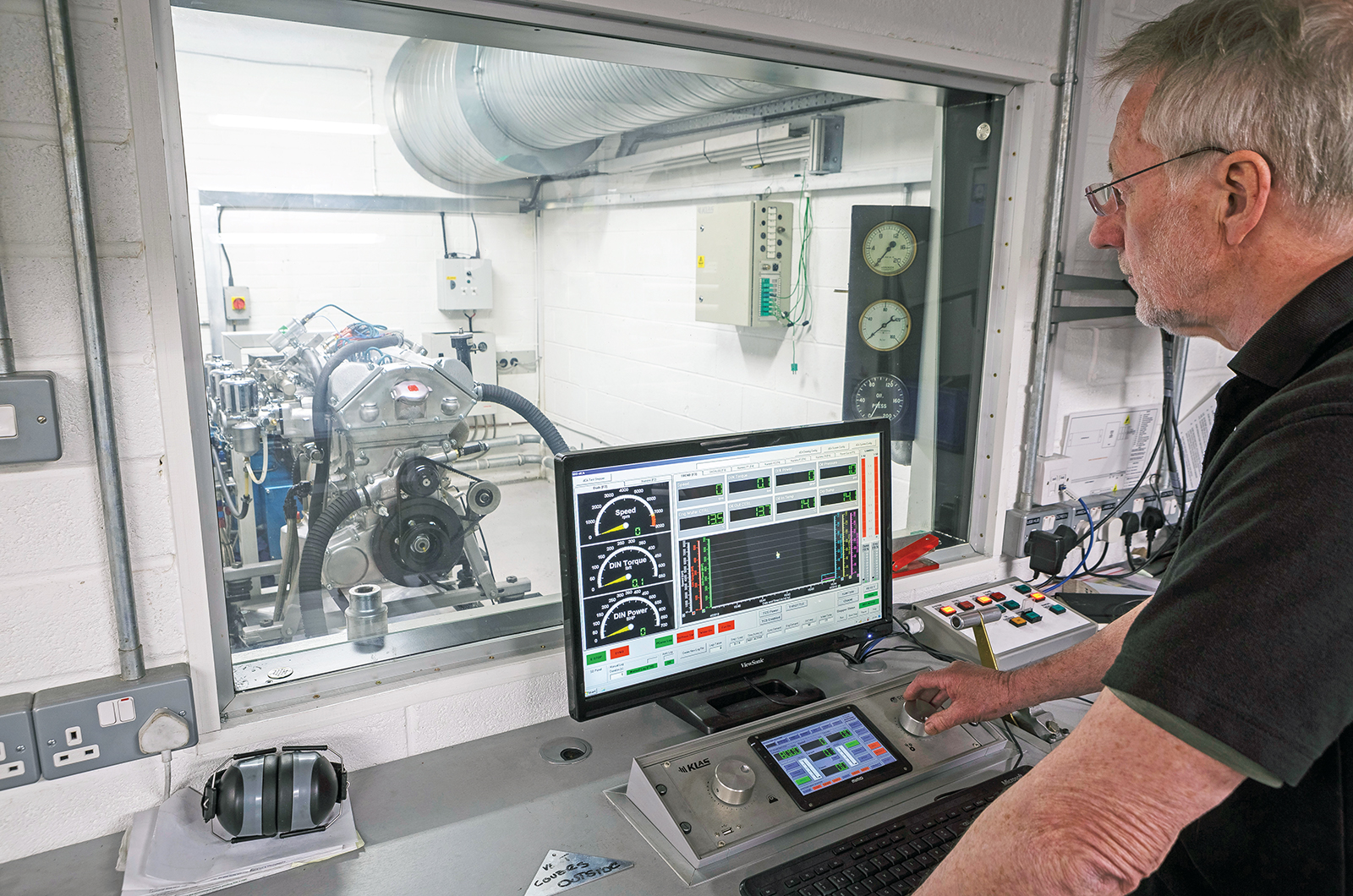

Andy Chapman worked for nine years in Aston Martin’s service department, later becoming an engine fitter, a road tester and an engine-shop foreman before branching out on his own as Chapman Spooner in 1975.

“Before leaving Aston in 1970, I aimed to learn as much as possible about Brico and Bosch injection,” he says. “Certainly the Brico system had many niggles. Whatever we did, we couldn’t get rid of its flat-spots. I was led to believe the black box needed more functions. There was a light-throttle problem that was not rectified, but at full throttle it pulled like a train.

“The factory modified the control box and fitted a new inlet camshaft, but this didn’t solve it. Air and water senders were a problem, and if mechanics did not replace the ‘O’ rings when injectors were removed, they leaked into the manifold.

“There were also problems with a vacuum pipe to the control unit – which kinked – and bad electrical connections. A later thought I had was that the mixtures were too weak to overcome the drying out of the manifolds at idle. But it had so much promise and I think a modern electronic ignition system would help. The DB6 MkII auto was very lively to 60mph with Brico.”

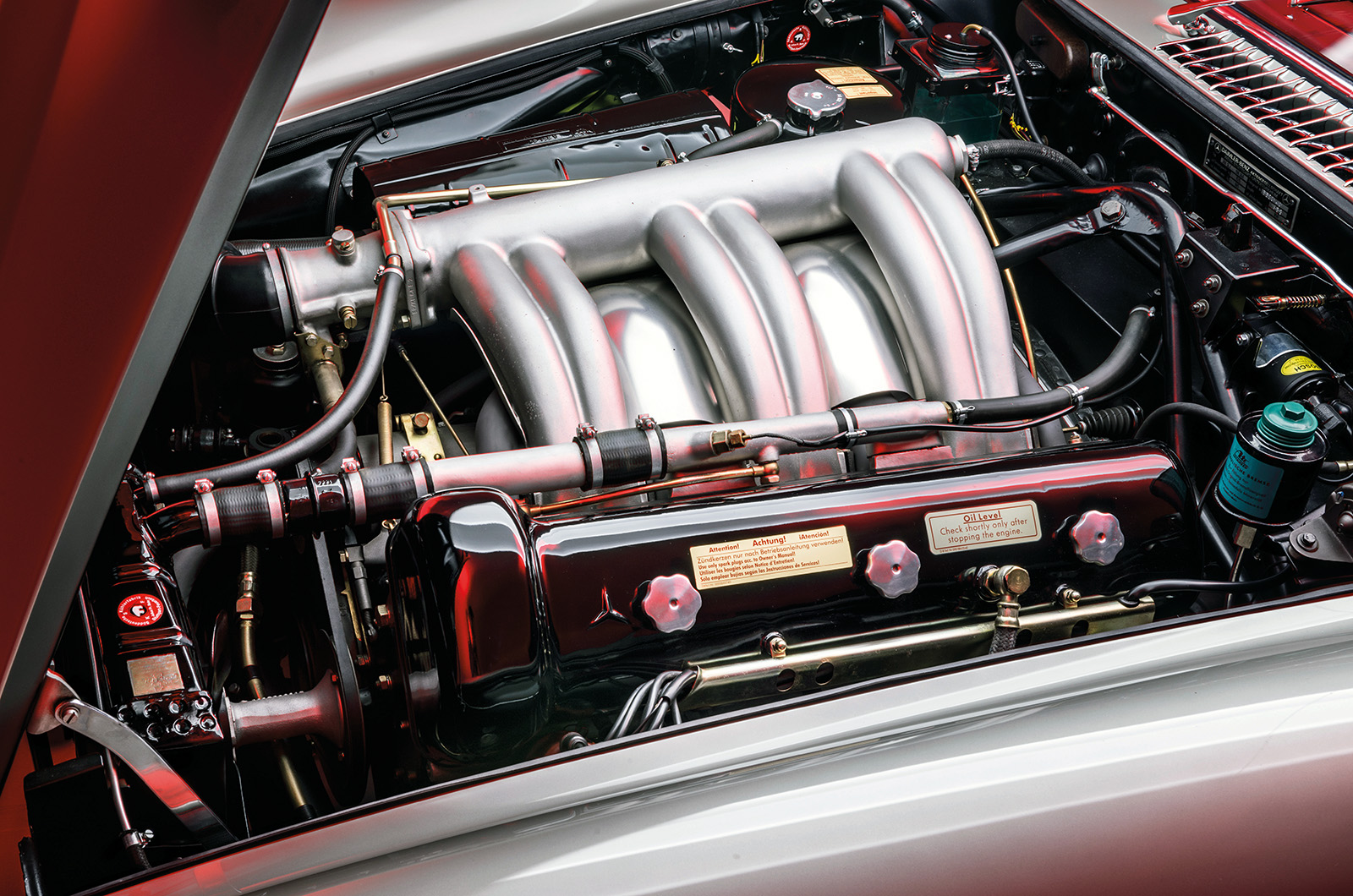

“The Bosch system on the V8 also had its problems,” Chapman continues. “They needed careful setting up; when this was carried out the cars ran well. The injection pump was in the middle of the ‘V’, with engine heat affecting the settings. The Opus ignition system was not up to the job and the engine ran rich at high revs.

“The tappets also needed to be adjusted regularly to hold tune. Even then emissions regulations could not be met, and Weber carbs proved more successful.”

A brief history of electronic fuel injection

The Mercedes-Benz 300SL had the first production mechanical direct-injection set-up

In the 1950s, America was booming and was the world’s richest country, with hard-won innovations from WW2 trickling into the consumer market. Stuart Hilborn, who had served in the Army Air Corps, started experimenting with aviation-derived mechanical fuel injection for cars.

General Motors clocked the benefits that Hilborn’s system – and others – offered compared to a carburettor, and Chevrolet’s mechanical ‘Ramjet’ fuel injection came in 1957, giving its C1 Corvette electrifying pace. GM wasn’t the first to use a production mechanical set-up – that was Mercedes’ direct-injection system in the 300SL – but home-grown rivals didn’t like GM’s new technical edge.

Fortunately for Chrysler, US specialist Bendix was busy getting ahead of the curve. Mechanical injection required pricey precision equipment and, in cars, could sometimes be outperformed by a finely fettled carb. In Bendix’s ‘Electrojector’ set-up, each cylinder had its own electronically triggered injector. Impressed, Chrysler made it available on some models.

The date 28 September 1958 marked the official production introduction of an electronic fuel injection (EFI) system. Sadly, if predictably, the optional $637 Electrojector (over £5000 in today’s money) was ruinously unreliable. Only 35 Electrojector cars were made and most were later retrofitted with carbs.

Even today, an Electrojector system wouldn’t be unfamiliar to those used to EFI, and it wasn’t a new idea: in 1940, Alfa Romeo tested a prototype 6C-2500 on the Mille Miglia with Ottavio Fuscaldo’s simple EFI system, before war got in the way.

Chrysler bailed out of the partnership, but Bendix persisted and licensed its patents to Bosch in 1965. Bosch delivered its first ‘D-Jetronic’ EFI set-up in the 1967 Volkswagen 1600.

Better hardware and falling costs meant a wider roll-out of the technology and, as emissions controls tightened in the 1970s, EFI rose to dominance due to its improved drivability, efficiency and precise mixture control. By 1990, electric fuel injection had finally found its feet and became practically standard across the board.

Additional words: Lewis Kingston

CHECK OUT THE ASTON MARTIN CARS FOR SALE IN OUR CLASSIFIEDS

READ MORE

Don’t miss our Aston Martin Greatest Hits special

Buyer’s guide: Aston Martin DB7

Aston Martin reveals reversible EV solution for classic cars

Martin Buckley

Senior Contributor, Classic & Sports Car