South Cerney Engineering has been around since the mid-’50s, supplying engineering services to garages in the days when they repaired rather than replaced major components.

The rural location means that farmers have been good customers, too: it’s all paying work.

Keith Boley of the respected Ashton Keynes Restorations bought the firm more than 40 years ago because it complemented his activities, while still earning its bread-and-butter as an individual entity serving the workshop trade.

But the rise of the ‘crate’ engine – in a culture where you can buy a new runabout for £150 a month – has led to modern-car work taking a much lesser role.

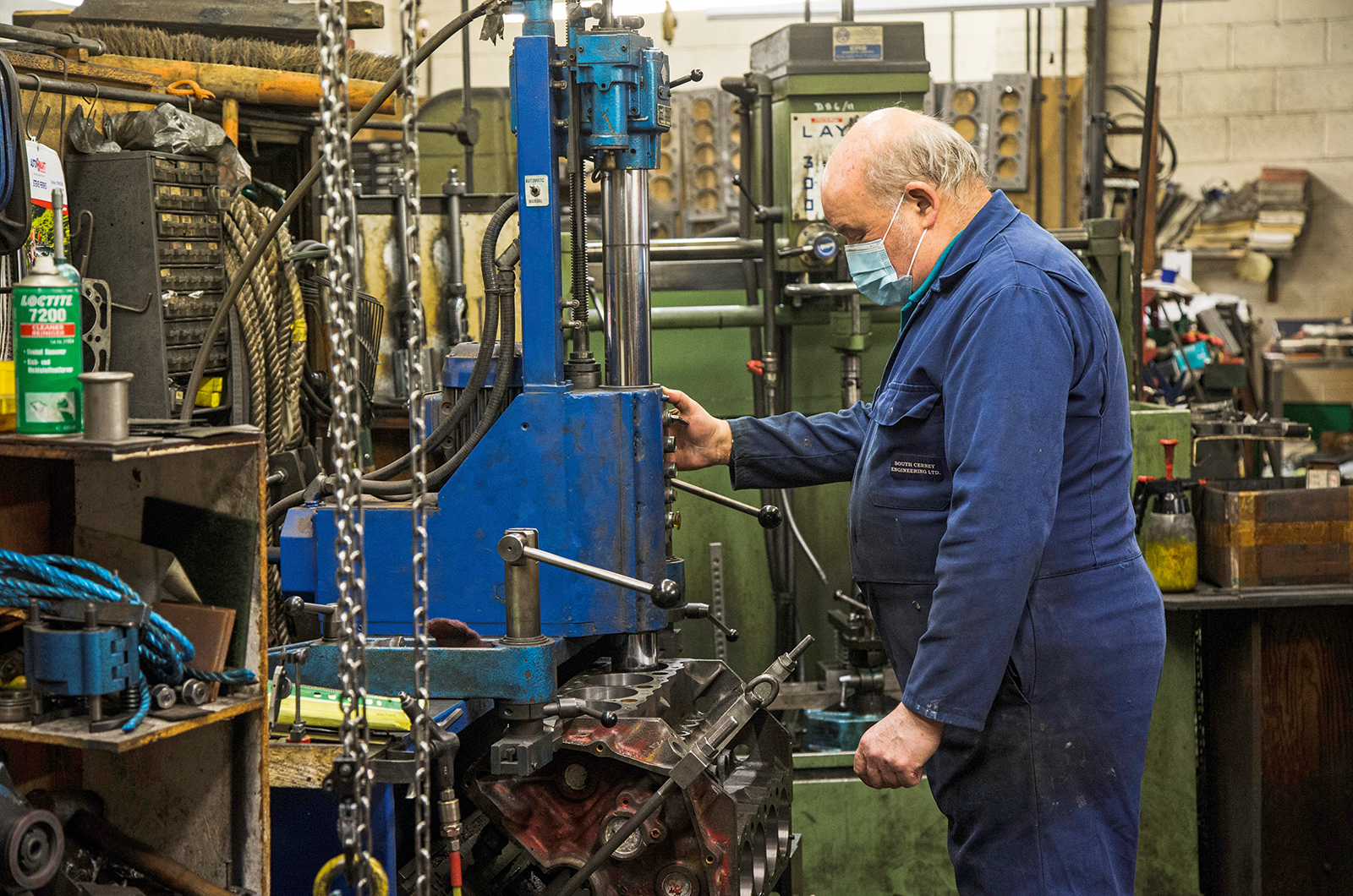

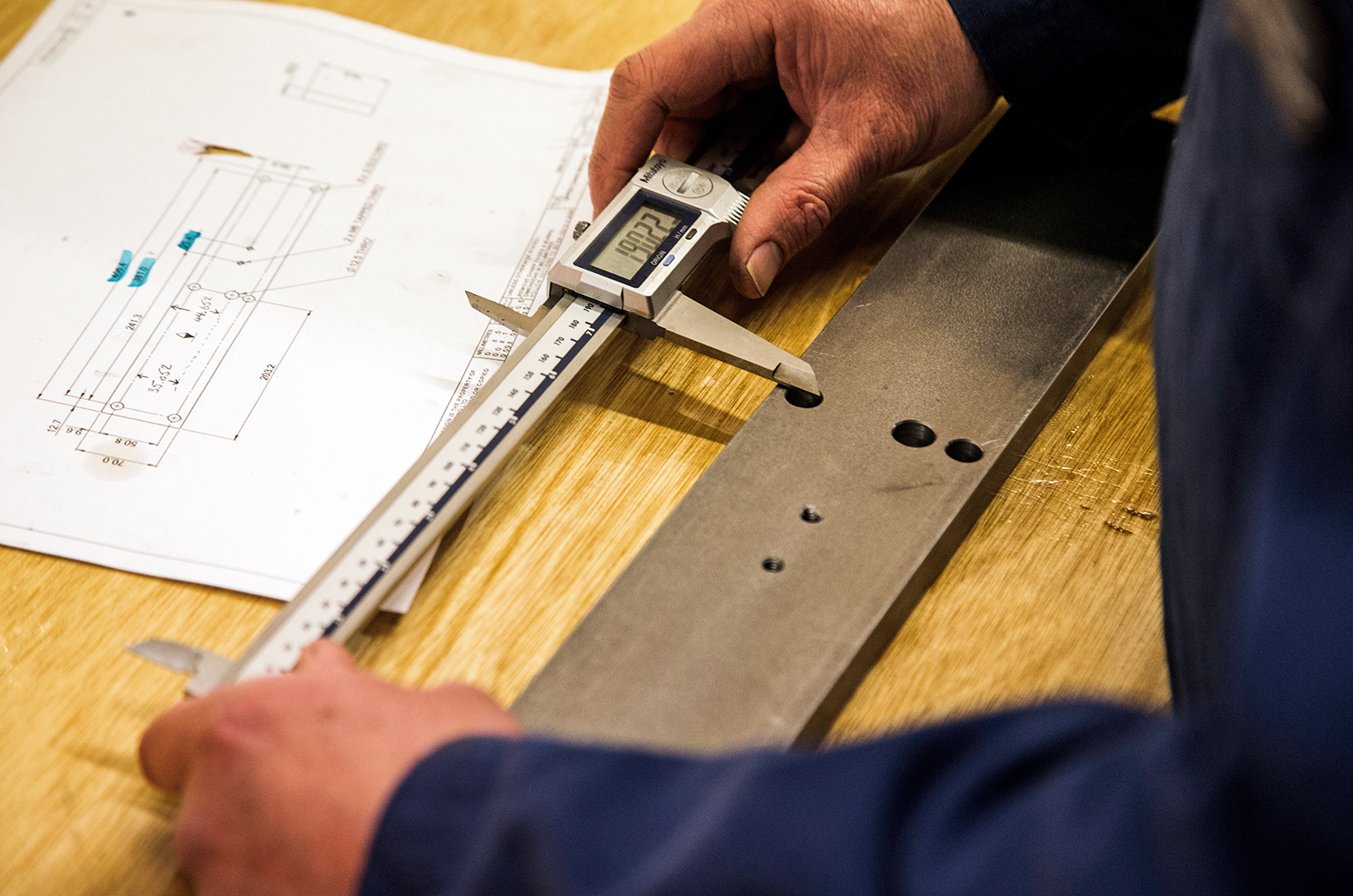

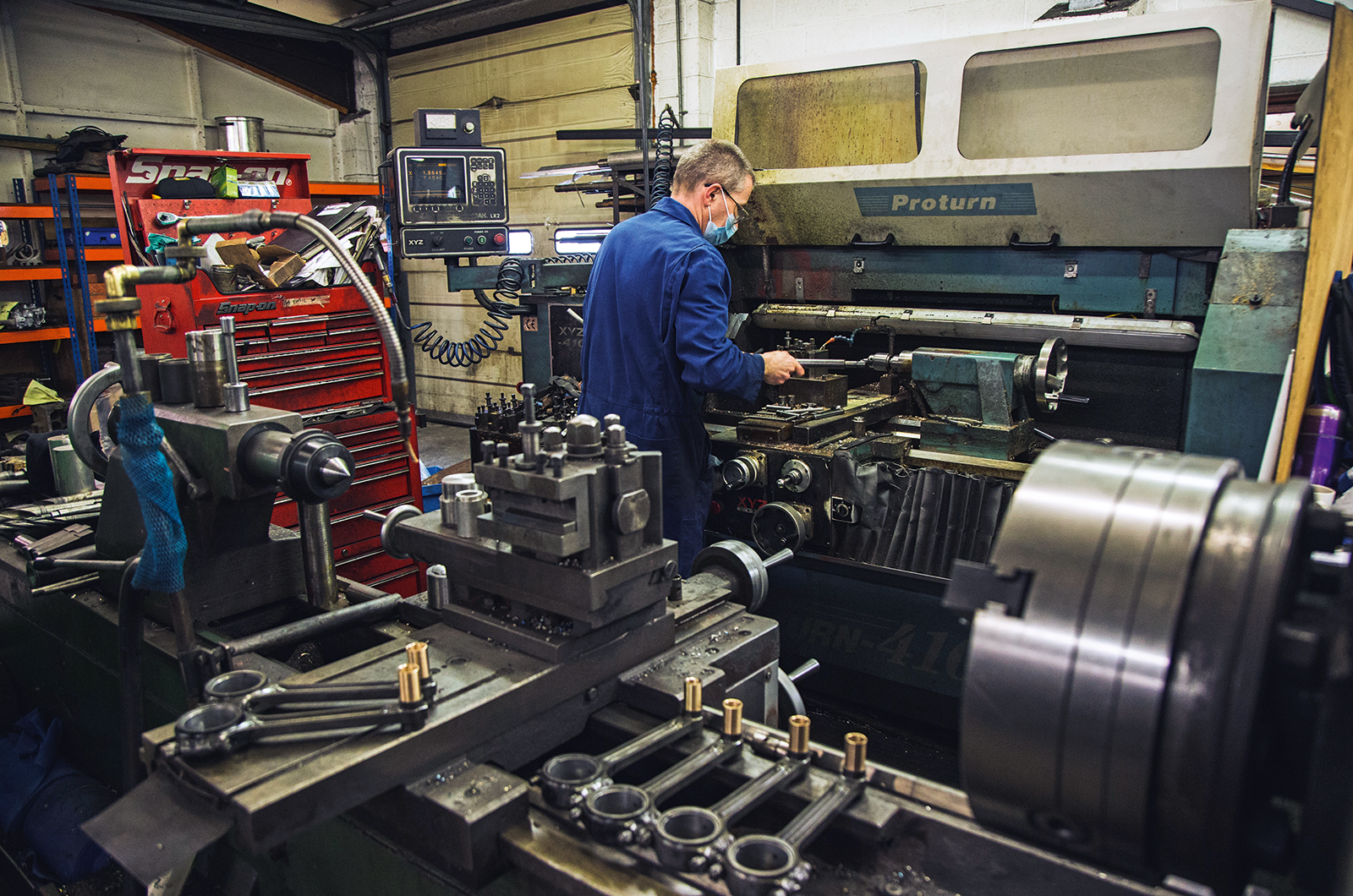

All tasks are tackled at South Cerney Engineering

Now SCE has moved into a new phase under Jonathan and Matthew Wills of Cotswold Classic Car Restorations.

With its skilled staff and range of machining services, the benefits to its parent company are obvious.